polySpectra may be best known for making ideas real through advanced additive manufacturing and accelerating innovation through methods that best suit the consumer.

As featured in our collaborative webinar earlier this year, polySpectra is taking a step toward making our COR Alpha resin available to more Asiga users.

You can now make your ideas real with COR Alpha for the following applications:

- Connectors

- Enclosures

- Housings

- Fluidics

- Brackets

- Jigs & Fixtures

- Tooling

- Gears

- Wearables

polySpectra’s mission is to create engineering-grade additive materials that aid designers, inventors, and engineers in making their ideas real via design, printed parts, resin, and innovation partnerships. One of our most valued partnerships is with Asiga–providing the most rugged resin available for their printers.

Asiga Printers Work For Aerospace, Automotive, Rapid Tooling, And More

Asiga launched the world’s first LED based DLP 3D printer to initiate the affordable desktop stereolithography revolution and change the future of digital manufacturing. Asiga printers are recognized for their industry-wide compatibility.

Earlier this year, polySpectra and Asiga announced polySpectra’s COR Alpha resin to early adopters. Asiga created a customized version of its Pro 4K printer that enables it to work with COR Alpha resin. Since then polySpectra has extended the use of Asiga’s other printers, including the Pico, the Max and the Max X.

Until recently, the most popular applications for Asiga’s printers were digital dentistry, audiology production, and jewelry. However, with the introduction of COR Alpha, polySpectra now enables Asiga printers to solve real-world problems in the aerospace, automotive, rapid tooling, and defense industries.

Broad Deployment Across All Asiga 3D Printers

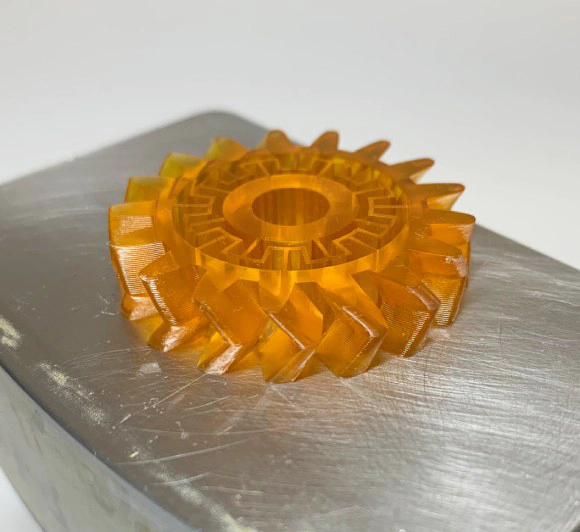

COR Alpha part printed on Asiga Pro 4k

Asiga Pro 4K.

As a larger format floor-standing 3D printer (122 × 69 × 200mm) the Pro 4K offers precision, reliability and speed for the most demanding production applications. COR Alpha works best on machines like the Asiga Pro 4K, to produce robust parts with fine features like those shown in the photo.

COR Alpha part printed on Asiga Max

Asiga Max.

Asiga’s Max series is composed of repeatable and precise desktop 3D printers (119 × 67 × 75mm) including the original Asiga MAX. In the photo shown here, you can see the same part printed with COR Alpha on this smaller format printer.

COR Alpha part printed on Asiga’s Pico

Asiga's Pico.

The Pico (30 × 40 × 76 mm) has the smallest build head area in the Asiga printer line. The same printed part shows crisp details and maintains great mechanical performance as well as high HDT and chemical resistance.

polySpectra is now making its COR Alpha resin available to Asiga printer owners who would like to start using it for their applications. Learn more about Asiga, polySpectra, our partnership and order COR Alpha resin.